HISERV 500

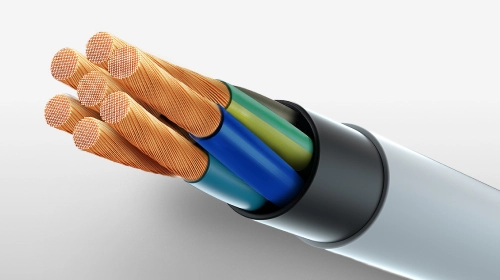

● Plain copper conductor, ultra-fine wire

for TOPSERV® 110:

1 mm² = 19x0,25 mm

● TPE-E core insulation, halogen-free

● Core identification:

Power supply cores black with imprint U1,

V2, W3 and earth core green-yellow,

Control cores black with imprint BR1, BR2

or nos. 5-6 and 7-8 for the 2-pair-version

● Screening of the control cores in pairs with

Al film, tinned drain wire and tinned Cu

braid; single pair with tinned Cu braid only

● Control cores stranded in pairs and laid up in layers together with the power supply ores

● Fleece wrapping

● Overall screening of tinned cu braid, visible

coverage min. 80%

● Fleece wrapping

● PUR-outer sheath, flame-resistant

● Colour petrol (RAL 5018)

|

Rated voltage :

|

Uo/U 600/1000V

|

|

Test voltage :

|

4000V

|

|

Insulation resistance :

|

(+20°C):≧20MΩx km

|

|

Bending radius: :

|

stationary : 4 x cable diameterØ

flexible : 7.5 x cable diameterØ |

|

Temperature range :

|

stationary : -40°C - 90°C

flexible : -40°C - 90°C |

|

Radiation resistance :

|

≤80×10cJ/kg

|

|

Flame retardant :

|

IEC 60332-1

|

Order Number |

Number of cores × Nominal cross-sectional area mm² |

Cable diameter ~mm |

Copper weight ~kg/km |

Cable weight ~kg/km |

316100 |

(4x1,5+2x(2x1,0)) |

12,6 |

186,0 |

242 |

316101 |

(4x2,5+2x(2x1,0)) |

14,6 |

232,0 |

318 |

316102 |

(4x4,0+2x(2x1,0)) |

16,0 |

308,0 |

415 |

316103 |

(4x6,0+2x(2x1,0)) |

19,2 |

420,0 |

575 |

316104 |

(4x10,0+2x(2x1,0)) |

22,8 |

647,0 |

805 |

316105 |

(4x16,0+2x(2x1,0)) |

26,0 |

918,0 |

1122 |

316106 |

(4x25,0+2x(2x1,0)) |

30,0 |

1402,0 |

1585 |

316107 |

(4x35,0+2x(2x1,0)) |

30,4 |

1882,0 |

2185 |

316108 |

(4x50,0+2x(2x1,0)) |

36,2 |

2574,0 |

2977 |

● PUR-outer sheath flame retardant, low adhesion, resistant to hydrolysis and microbial attack, halogen-free

● These highly flexible cables are fitted with an additional overall screen to assure EMC compatibility, i.e. the protection against electromagnetic interference

● The materials used in manufacture are cadmium-free and contain no silicone and free from substances harmful to the wetting properties of lacquers